Fascination About Copper Foil

The Buzz on Copper Foil

Table of ContentsThe Facts About Copper Foil RevealedOur Copper Foil PDFsThe Facts About Copper Foil RevealedHow Copper Foil can Save You Time, Stress, and Money.8 Simple Techniques For Copper FoilOur Copper Foil Ideas

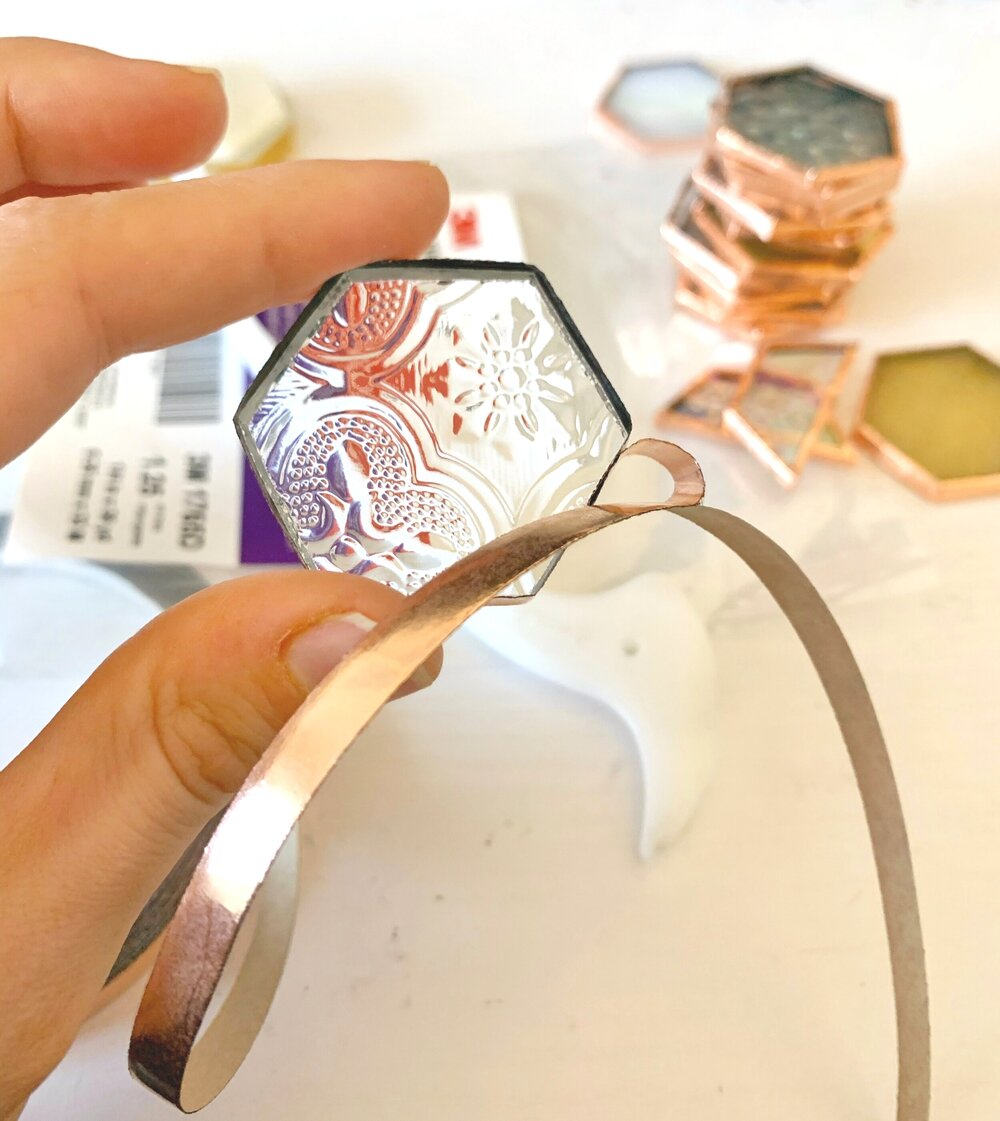

This method can be made use of on any product that can stand up to the heat of the soldering iron-- as much as 1000 levels Fahrenheit. Add a ring, loop or other finding in the soldering process and the glass is transformed into a part that can be made use of as an appeal, necklace or link.Make a perception, get rid of the foil after that trim at the perception. ACTION 2 ACTION 3 Neatly press the foil against the slide. Making use of a burnisher, smooth the foil so it is pushed safely onto the slide as well as smooth. ACTION 4 Grasp the slide with tweezers kept in a third hand so you can work hands-free.

Solder will not stay on the aluminum foil if it isn't fluxed correctly. STEP 5 While servicing a heatproof surface, using a blowpipe or collaborating with the soldering pointer in place on the soldering lantern, spark the lantern and also permit the pointer to warm up. Press the idea to the solder so a little of solder is collected.

Some Known Incorrect Statements About Copper Foil

STEP 7 Permit the assembly to cool, then wash it with warm water and also soap prior to utilizing in a style. "I just desire to say thank you for all the different suggestions Fire Mountain shares with us, your customers, so that we can attempt different methods. copper foil.

Many thanks. Best regards," - Nora Have a concern regarding this job? Approval to copy this guideline sheet is provided for non-commercial educational objectives only.

A Biased View of Copper Foil

In an electrodeposited copper manufacturing procedure, the copper foil is transferred on a titanium revolving drum from a copper service where it is linked to a DC voltage resource. The cathode is attached to the drum as well as the anode is immersed in the copper electrolyte remedy. When an electrical area is applied, copper is deposited on the drum as it rotates at an extremely sluggish rate.

The slower the drum rate, the thicker the copper obtains and also vice versa. The copper is attracted and built up on the cathode surface of the titanium drum. The matte as well as drum side of the copper foil experience different treatment cycles to ensure that the copper could be ideal for PCB fabrication.

The process is controlled in such a method that the product just obtains longer and does not alter its width. As the sheets can not be created any type of further in this state (the material has actually work solidified thoroughly) they undergo a warm therapy and also are heated to concerning 550C. Figure 2: Rolling of copper foils Figure 3: Copper aluminum foil products.

Rumored Buzz on Copper Foil

Obtain the most check out here up to date news on brand-new promos, exclusive offers, and also new kid on the blocks.

- The major function for foil used in discolored glass job is simply to fold over the edge of the glass to permit the edges to be soldered together. Typically, regular copper foil is utilized, nevertheless, plain copper aluminum foil can cause an issue if it is made use of on glass that is relatively clear - the inside edge of the aluminum foil can be translucented the glass and it will cause a "copper halo" along the seam.

If you prepare to leave the solder joints silver tinted, use silver backed foil. If you prepare to use black patina on the solder joints, use black backed foil. - Copper foil is often used as an edging product on glass accessories, bevels and also for various other craft jobs. If the glass is relatively clear, the very same "halo" issue noted above will occur.

The Facts About Copper Foil Revealed

Silver Both Sides Aluminum foil allows you to have a silver front side to a craft job without the need to solder the aluminum foil. It has a sticky support like the copper foil aluminum foils.

Numerous Cut tools are suitable for reducing copper foil - copper foil. You can determine which one is finest based upon your application, the amount of area you need Get More Info to operate in, whether you're making straight or curved cuts, and also the amount of precision called for. If your copper foil has a sticky support, the amount of pressure you use will determine whether you punctured the just the foil layer, or both the aluminum foil and its backing.

Cut makes a vast variety of blades and cutters that work well. Our scissors likewise function well for several applications.

Facts About Copper Foil Revealed

Copper aluminum foil is currently utilized for a wide variety of applications in the electro-engineering industry owing to its superb conformability, high electric conductivity, and shielding capabilities. Copper aluminum foil can be soldered, which makes it optimal for easy grounding applications. Double-sided tin-clad copper is made use of where maximum resistance to the exterior atmosphere is required.